Dwight Simpson, owner and founder of Simpson Properties Contracting, is an Electrical Technologist by day and Real Estate Investor/Builder by night located in Toronto, Ontario. Dwight and his young family are doing an extensive renovation on their Toronto home which is being documented for his YouTube series titled “Invest.Remodel.Repeat” which will be released in early 2020. He is candidly sharing his experience with us and all the exciting details of renovating their 1960’s backsplit into an innovative modern dream home that features Warmboard radiant floor heating.

Read MoreCanadian Homeowner Reports Back on First Winter with Warmboard

In this installment of Warmboard Works, we talk to Remko T. from Ontario, Canada, who built his home in 2018 near the shores of magnificent Lake Erie. He’ll recount for us his experience building and living with Warmboard in his family’s 2,650 sq ft home and 1,100 sq ft detached garage.

“We chose Warmboard for our new home that we built last year and couldn’t be happier! We considered all the options available for floor heat and found that the extra panel cost for a Warmboard system was worth it. We were not disappointed! The panels arrived on time and the framers had no trouble putting it in following the layout plans. House construction can be tough on subfloors but Warmboard held up amazing!

I also waited on installing the pex tubing until the walls were up and the plumbing, wiring and exterior wall insulation was done. I did the custom router loops myself with the template kit provided. I ran all the pex lines according to the plans provided to the manifold locations just before the drywallers started.

We decided to keep it simple by making one heat zone for each the basement, the main floor, the top floor, and the detached garage. The hot water heater is another zone. We did not use slab sensors anywhere, just thermostats in each zone.

The boiler we chose is a 160,000 btu IBC Canadian-made boiler. It has 5 built-in zone controls and an outdoor reset thermostat as well. It’s a very simple and well-built boiler and incredibly easy to operate.

Overall, we are thrilled with our warm floors! Our Warmboard system heats the house very evenly and very comfortably. We are pleased with the fast response to both raise and lower the temperatures in the house as desired. I run the water temperature in the floor between 110°-125°F which gives us great response times and is lightning fast! I’ve also noticed the heating keeps up easily when it is below 0°C outside. During the day we typically keep it at 19°- 21°C and at night we set it down to 17°C.

The cost to heat the house to 19°C and the garage to 15°C is on average $300-350 per month with propane @65cent per liter. This is a bit disappointing but I’m anticipating the cost will decrease at least 33-50% when natural gas comes through in the near future.

My wife and I love our Warmboard home and we can’t help but notice the lack of radiant heating and lack of Warmboard’s invisible comfort when we go to anyone else’s house.”

Streamline Design Ltd, British Columbia

Kevin Simoes of Streamline Design Ltd tells of his first experience using Warmboard. The Gabriola project is a post-and-beam home in British Columbia and features over 3000 square feet of Warmboard-R.

“We chose Warmboard for its ease and its convenience. The structure was built on an island, so we knew the construction costs were going to be high. Costs for using concrete for the radiant heating were especially high, so we knew that would not be a viable option. In fact, Warmboard was the cheaper option and definitely had a positive impact on the budget. Combined with its performance claims, Warmboard became the natural choice.

Working with the Warmboard has been a great experience. The design team was fantastic. They were responsive and easy to work with. They answered our questions promptly and produced working drawings very quickly. And while we provided only the architectural design (we were not the installers), the feedback from the contractor was very positive as well. The installation drawings provided were very helpful and easy to follow, and they were pleased with how quickly and easily [the panels] went down. The ease and speed of the installation was actually one of the great benefits with Warmboard. It definitely made an impression.

The homeowner was very pleased with the install and subsequent system performance as well. They have also remarked that they have really noticed the savings on heating costs.

Overall, we have had an incredible experience work with Warmboard. The team is very professional, easy to work with and always happy to help educate architects, installers and the clients. And you have a great product! The team at Streamline has been very pleased to team up with Warmboard on additional projects and we look forward to specifying the product on many jobs in the future.”

Kevin Simoes

Streamline Design Ltd.

Sustainable Edge, Toronto

In this Warmboard Works we hear from Mario Kani of Sustainable Edge, an Engineering firm in Toronto, Ontario.

For over a decade we have been using hydronic radiant heating and cooling in ceilings. The benefits of a fully hydronic house with moderate heating and cooling water temperatures and no recirculated forced air are many, including:

- Complements low energy envelopes which require lower heating and cooling capacities

- Provides better comfort

- Delivers healthy indoor air

- Promotes minimum noise in living spaces

- Requires minimal and smaller ductwork (ventilation only)

- Results in lower distribution energy (by using a pump instead of a fan)

- Increased flexibility for thermal supply source such as solar or geothermal energy

Locating the radiant cooling on the ceiling provides the maximum output for a specified design surface temperature. While we have designed several projects using concrete radiant ceilings, we have found that for wood construction, Warmboard is a natural match for ceiling installation, placed just behind the drywall. Warmboard is also an ideal candidate for radiant heating in the ceiling as well, able to provide either low- or high-intensity heating during winter months.

The principle of ceiling cooling is based on average surface temperatures between 60ºF to 70ºF over a large surface area, resulting in draft-free, low-intensity cooling. The cooling surface temperature needs to be high to avoid surface condensation. This system only does sensible cooling of the living space (i.e. no moisture removal) so that dehumidification needs to be done separately. For a successful ceiling cooling installation, the project’s attributes should be as follows:

- A high performance thermal envelope to minimize cooling loads through careful glazing selection and summer shading,

- Significant envelope airtightness

- 100% outdoor air ventilation without recirculation (also known as DOAS: dedicated outdoor air system )

- Ventilation heat recovery (preferably an ERV)

- Dehumidification of outdoor air with 45ºF to 50ºF chilled water (e.g. directly from ground water or via ground source heat pump) resulting in drier ventilation air than room air.

We look forward to using Warmboard–R, the thinner retrofit product in our next radiant ceiling project.

Mario Kani, B.A.Sc., M.A.Sc., P.Eng., LEED® AP

President, Sustainable EDGE

124 Merton St., Suite 507

Toronto, Ontario

Canada M4S 2Z2

contact [at] s-edge.com

416.477.2625

Sustainable EDGE designs using an integrated, holistic approach to system flows. Combining energy, water, air, nutrient and organic resources in their engineering methodology allows their clients to achieve the lowest possible greenhouse gas (GHG) and environmental impact. And where possible the project will make positive contributions to society and the environment.

Sustainable EDGE believes in good design, enlightened by sustainable principles and fitting best to the dynamics of each building goals.

They offer the following Consulting, Designing, Planning and Net Zero engineering services.

vivZ architects, EDMONTON

In this Warmboard Works we hear from Vivian Zhao of vivZ architects in Edmonton, Alberta. In 2015, Vivian used Warmboard in a 12 unit condominium unit in Edmonton. Here’s what she had to say about her experience with Warmboard.

Grovenor Condominiums. Edmonton, Alberta

“With this project we used to 2 lots and combined together. The result is 12 townhouse units with a shared basement and underground parking.

We wanted to use infloor heating from the very beginning. One of the managers on the project had heard of Warmboard (but not used it), and thought it might be a good option, allowing for much faster installation, especially compared to the alternative, gypsum concrete.

So I started to look into Warmboard. And aside from the benefits of having a faster installation, there were many other benefits as well. You can use a much wider variety of floor finishing materials. I read through all of your online material and contacted your sales rep in Vancouver. I then flew out to Vancouver with my husband, and we met with your sales rep who showed us a couple of active Warmboard jobs in the area. It was very helpful to go on site and see the Warmboard still exposed. And we were able to see the control systems as well. This was very helpful. At that time I felt it would be the right product for our project. I began working with your design team in California, and soon after we were making payment and coordinating the shipping.

Working with design team was good. The team was very cooperative in designing the system efficiently as to keep costs under control. They were very helpful.

Much of the construction took place during the winter. So we put the panels in put could not yet put in the tubing because of the freezing temperatures in Edmonton. It’s just not possible. We did cover the panels a couple of times during the construction process with Rahm board, first during the winter and again in the summer after the tubing was in. This did cause additional labor for us, and it was time consuming. We would have loved to be able to rent cover panels from you as a temporary covering. Obviously in a smaller house, this wouldn’t be a big deal, but on a large multi-res project like ours, we think this would be a good thing to offer in the future.

This occupants of the building have been living with Warmboard now for 2 full heating seasons, and I can tell you the performance works very well. It is very satisfying. Our residents are amazed and how comfortable it is. And our gas bill is very, very low. Warmboard is saving us a lot of energy for sure.

I would definitely recommend Warmboard in the future and hope to use it in more projects.

vivZ architecture

14021 23 street, Edmonton

780.908.2637

Pro-Star Mechanical, BRITISH Columbia

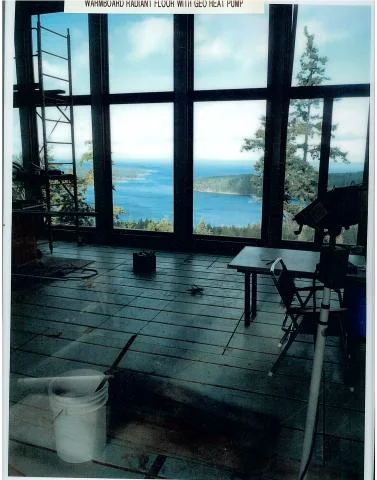

Wilf Scheuer of Pro-Star Mechanical talks to us about a unique build on top of a mountain on Gulf Island in British Columbia.

“We’ve been quite happy with our Warmboard experience, had no issues whatsoever. It was easy to work with, and we’ve done a number of Warmboard projects. I think we may have done the first Warmboard ever in BC and we recommend it highly.

Warmboard was a good product for this particular job because it’s on a remote access Gulf Island. The project is on the top of a mountain above Mayne Island, so it’s quite cold up there as compared to being lower down. It took them five years to finish the job, but it’s a really beautiful architecturally designed home, the best views in the world I’ve ever seen. It overlooks the ocean, Active Pass, and the other islands.

So when talking to the client we gave different options and both the client and ourselves found that Warmboard was the best solution. The owner wanted a high quality system that was compatible with a geothermal heat pump because we drilled three holes 350 FT deep into the mountain.

With the combination of Warmboard, geothermal and the water furnace heat pump he’s got an excellent system that runs reliably and is economical. It’s economical to heat the home as compared to other fuel pipes in the Gulf Islands, which would normally be oil, propane or straight electric, so he’s probably saving 70% of heating costs as compared to traditional sources and it has really good performance.

We find that the heat is very, very even throughout the home and is quite satisfying. It has a lot of glass in there too so in homes with large amounts of glass it’s important to have good distribution systems for your radiant heat so that heat is applied evenly throughout the home so you’re not getting cold sitting by a window.

Overall, Warmboard seemed to be a really neat package that had good performance of heating; he liked the idea of a smooth floor, extra structure, and that he could use it for temporary heating even before the floor was finished.

Aside from the fact that Warmboard gives you very even heat, it seems to move the job along quickly. For the heating contractor it gives you a good guide for installing. The installation ease and performance of the product is superior to other methods like concrete topping or stapling underneath and insulating. With Warmboard you just have to snap the tubing in there with a rubber mallet.

We’ve worked with Uponor quite a bit and Watts, and in slab, under slab, under joist, topping on top of plywood, ceiling radiant, wall radiant, virtually every way of possibly doing it, and I think the Warmboard situation probably is the simplest and easiest… an elegant solution to radiant heating a home.”

Pro Star is a family owned and operated full-service mechanical contracting business dedicated to serving the HVAC needs of Vancouver Island and the Gulf Island communities with honesty and integrity since 1988.

Victoria @ prostar-mechanical.com

www.prostar-mechanical.com

Find them on Facebook

The Boiler Guys, Toronto

In this Warmboard Works we hear Alex Genzer of The Boiler Guys speak about a remodel project in Toronto. They had initially chosen an alternative radiant heating method for their home but decided to make a last minute switch to Warmboard due to several concerns about Staple-up.

Toronto Skyline

“I’ve done a couple of Warmboard jobs now and they’ve all been really good. With this job we were originally asked to do Staple-up throughout the whole house, but there were several concerns with the floor which the original general contractor didn’t notice. The quick and easy solution was to put in Warmboard.

Once we made the switch, it went very smoothly. Probably the quickest install I’ve ever done. The people doing the subfloor were able to put it down in about a day, and then I came in and laid the tubing down.

The great thing about Warmboard is that the tubing took me only a couple of hours to lay down. It literally clips right into the grooves. I ran it to the mechanical room and had it pressurized all within a couple of hours, whereas other systems you usually have to budget the whole day.

The fact that we can install the systems very quickly compared to traditional ways is a definite benefit when using Warmboard. Speed of install is so precious here. You’re not on your knees as long, and the tools are much simpler. We don’t need zip ties, we don’t need staples, and they have that weighted roller for the tubing. It literally takes one person with an unwinder and PEX. It goes down as quick as anything else, and it’s cleaner than anything else. Not to mention it actually looks cooler because the pipe is dead straight, absolutely straight, and then it turns and the radiuses are perfect. Even the ‘Wow Factor’ you get when the customer sees the nice, new job is something you just don’t experience with Staple-up.

I’ve also noticed that the average temperature for water with Warmboard is lower than Staple-up or Onyx systems. We can do around 80 or 90 degree water temperatures with Warmboard whereas any other system you’d have to do up to 140 degrees. Everyone in the hydronics trade knows that the lower the water temperature the more efficient [the system] becomes, and Warmboard has the lowest water temperatures. It just does.

A lot of people are initially deterred by the fact that it is a more expensive product. But then you compare it to other systems that require other stuff. For instance engineering has to be done differently, we need to create bigger joists, we need a floor leveler, etc., – it just becomes a big nightmare. When you really compare it, it’s around the same price at the end of the day.

So when other customers are talking about the price I let them know that when they choose this product early on, the initial part of the job might be a little more than doing in-floor concrete or Staple-up. However, when you consider the fact that we don’t need all of those other trades to accomplish the same thing, it actually ends up being around the same price. And once I install it the customers love it. They love it and we love it.”

The Boiler Guys fulfill jobs of any capacity whether it is boiler repair, Warmboard installation, radiator replacement, in-floor radiant heating, snowmelt or any service to do with hydronic heating. The products they use are of the highest quality. The manufacturers they work with stand by them to provide the best customer service and the most effective solution for cost and energy efficiency. The Boiler Guys’ seasoned knowledge and years of experience is there to help ensure every client makes a wise, informed decision with each project. This is Alex and his team’s mission, and it’s their vision to continue to serve for years to come. Find them at theboilerguys.com or call 1-877-836-6708.

Michael Diacon, SASKATCHEWAN

This Warmboard Works features the addition/renovation of a home in Moose Jaw, Saskatchewan by the homeowner. The project included an overhaul of the old heating system to make way for a more effective, energy efficient alternative.

It was during the renovation and addition to our house that we decided to a look at updating our heating system. One of my sisters had had in-floor heating in a couple of her houses, so I was familiar with the concept and had always enjoyed it. After some research we decided to go with in-floor heating, partially due to efficiency; furnaces tend not to be as efficient as hot water heat, and partially due to the difference in comfort.

This prompted research into the various methods of in-floor heat: staple-up, lay-down, the one where you pour concrete over top, etc. And then I came across Warmboard. As I continued researching I realized that Warmboard was the most efficient at distributing heat. That’s what sold me in the end.

I did the majority of the installation work myself, however I did have a couple of individuals with some experience working on construction projects. They were impressed with how easily the Warmboard-R went down, as well as how heavy and sound the Warmboard-S panels were. Everyone that either helped with the installation process or witnessed it was quite impressed with the ease of it all.

Most remarkable though, is the follow-up from the company. Warmboard has been in touch with me many times over the course of the project. Right from the beginning when I first sent the query in, through the completion of the project, down to an email a few days ago asking for feedback and input. The company looks after you every step of the way.

I turned the heat on in March, so we’re just ending a full year of heating. It’s been wonderful to walk from one area to another and feel nice, comfortable warmth. Even my wife has commented how evenly heated it is, and the lack of cold spots. I’ve also noticed that when I don’t have all of the loops on, as I walk from one area to another I can actually feel the difference walking from a warm area into a cool one. Not just the heat on the floor, but the actual space itself feels much cooler. I’m very impressed with how well it keeps the whole house warm.

Michael Diacon is a journeyman electrician with 30 years experience, currently working for SaskPolyTech training 2nd, 3rd and 4th-year apprentices as well as running an electrical contracting company, 4D Electric, with his daughter and son-in-law.

306.631.4867

WWmdiacon7 [at] icloud.com

Jason Mancuso, CALGARY

This installment takes us to Calgary, where homeowner Jason Mancuso discusses his experience with different radiant heat methods, and why he chose Warmboard for inclusion in his 5,100 square foot custom home.

Downtown Calgary

We knew from the very beginning that we would be using in-floor heating in our home. Living in a radiant floor heated house is not new to me so I was familiar with the upfront costs, as well as the long-term benefits. I had built a couple of homes with my dad, tried a few other methods, and then we sort of stumbled upon Warmboard.

I liked the different approach that Warmboard took. We have experience with placing pipe underneath the house, and we’ve also put it into Styrofoam and then poured lightweight concrete over-top. By contrast, Warmboard is a different method, and even before using it I could see that it was a lot easier for installation. It took a lot less prep as far as the framing is concerned, and it doesn’t change anything about the construction process.

The whole installation process is very natural. There wasn’t much prep-work needed. You already have to lay down a tongue and groove subfloor, so nothing really changes from the construction side until you put the piping in. After speaking with the contractors and different framing crews they confirmed that the procedure of building the house was the same as they were used to. There’s no interruption, no waiting for things to get done so that a contractor can come in. Everything flowed the way that it should. That was probably the best part about Warmboard, that it was very natural to the building process.

The only thing I would maybe do differently, through no fault of the product, is that through construction you get a lot of dirt and debris into the channel-way. By the time you’re ready to lay the pipe down you will have to spend some time vacuuming and cleaning to make sure the channels are nice and smooth. A bit of that was because we were building through the winter months, which obviously tend to be muddier and dirtier. Next time I will consider laying some ¼” sheeting over top immediately after it’s put down to protect it and minimize the dirt that gets in the grooves. It’s not really a fault in the product; it’s just a factor of when we built and how building procedures go.

We’ve been in the house for about 6-7 months now, so we’ve been able to experience the heat, especially right now in the colder winter months. We’re starting to get some –20ºC (–4ºF) days and the Warmboard has been great.

My parent’s house, where I grew up, had the pipes laid underneath the floor into concrete on the basement level, and in my parent’s temporary home, it was done with lightweight concrete over-top. In both cases, the response time was slow – between 1-2 hours. If you tweak the temperature you’re not going to feel it for a long while.

Now that we have Warmboard, you tweak the temperature and within 20-30 minutes you’re definitely feeling the house really increase in temperature. It’s much more responsive, much quicker, which in turn means you can turn it up a degree or two, warm it up, and turn it right back down again. You don’t have to leave it on for two hours, which keeps energy costs down.

I would recommend it; I might even use it in a future project. It’s not necessarily a product I’d use in a home I just plan on reselling. But as far as my own home, it’s probably one of the best features of the house. The house is very consistent, very clean, no dust floating around because there is no forced air. I would recommend to anyone building their own home to definitely use hydronic heat, and then furthermore to use Warmboard. It’s just a great way to heat your home, especially in our parts of the world where we get six plus months of subzero temperatures. And it definitely does keep your heating bill down, I can tell you that much.