This is the second post in a Warmboard Works series we’re doing with NeverSummer Construction located in Granby, Colorado. We’ll be checking in regularly to get updates on the project throughout the build and see the home come to life through interviews, photos, and videos. In this installment we talk again to Brad Line, one of the owners of NeverSummer Construction, to learn more about his tubing and manifold installation, hooking the system up and turning it on, and his experience installing finish flooring over Warmboard.

PROJECT DETAILS

Type: Single family home, new construction

Location: Granby, Colorado

Total Square Footage: 2,800 square feet

Lot Size: ¼ acre

Energy: Natural gas, Triangle tube boiler

You mentioned in the first post that it took one day to install the tubing with 3 people. Any other observations about the tubing installation process?

Using a rubber or dead blow hammer to hit the tubing in the channel as you’re placing it makes it go in really easy and fast.

What was your experience hooking the system up?

Hooking up all the manifolds was really simple, and the tools provided in the kit with the literature make it so just about anyone with some plumbing experience will be up to speed fast. I had a slight difficulty at first with the actuators but after talking with tech we both came to the conclusion as to why they didn’t seem to close which was that I didn’t have the thermostat call for heat for at least 5 minutes and then turn it off to make it cycle. It was amazing to learn the technology with the wax in the actuators and how it is really efficient but just takes a little bit to actuate. They have been working great and were really easy to wire up.

How many zones do you have?

This house has 8 zones with one of them being the garage floor. I would recommend to anyone doing a hydronic system to place the master bath and bedroom on separate zones. You will love the warm floor in the bathroom in the middle of the night and morning and also like the ability to keep the bedroom cooler at night while sleeping.

When you’ve had the system running, how has it worked?

I have been in the house for about 3 weeks now and I will say that it reacts really fast to turning it on and it does get the floor nice and warm when you are barefoot. I haven’t been in really cold temperatures yet but will update you once winter starts and we’ve had multiple days of subzero weather. I will say that I have the boiler set to a max of 120 degrees and think I will be turning that down because I do truly think it can be run at a lot lower temperature and be just as responsive and comfortable.

What’s been completed since the last post?

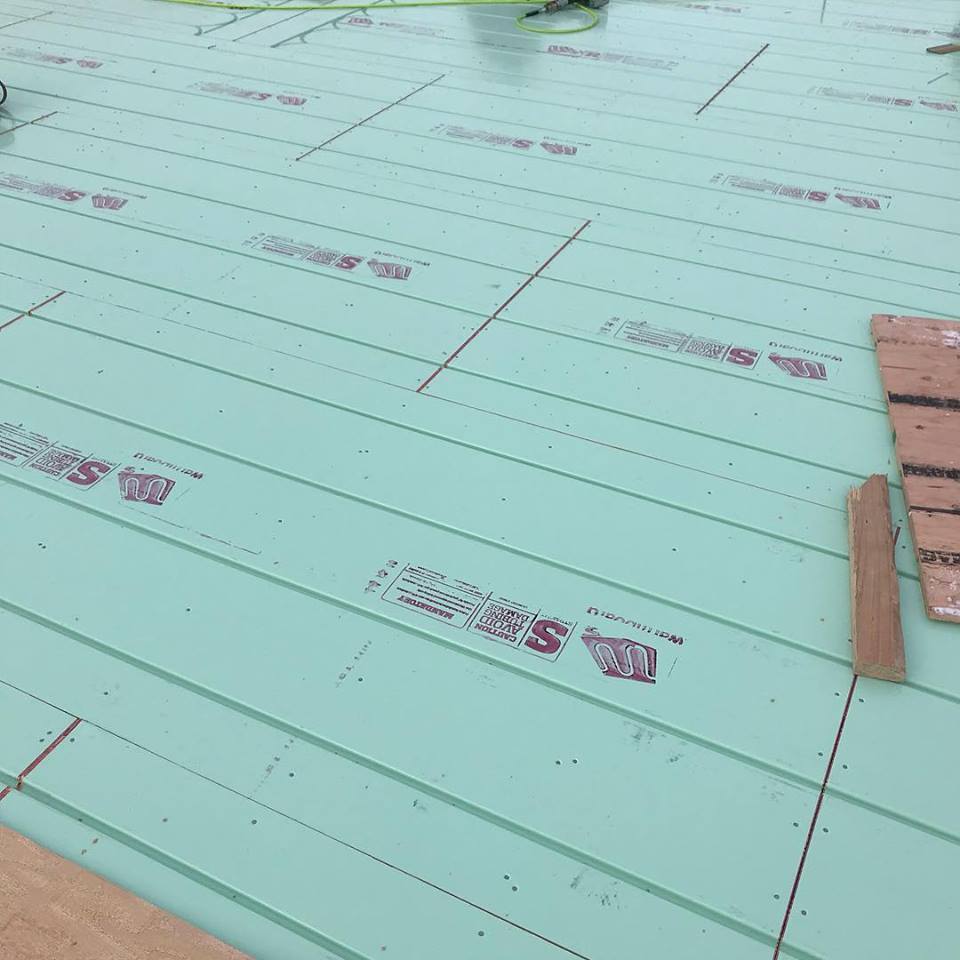

Since the last post I completed the boiler setup and got the radiant system running. I also finished installing the flooring. I would mention that flooring goes down really easy, similar to how you’d install any other substrate but with the convenience of being able to see the tubing.

Also, a good thing to note is that through the whole drywall process no tubing got damaged! Although when I was installing flooring and had some tools set up, I dropped a sharp object on a tube and put a hole in it, but it was really easy to repair. It is worth noting that this is important because although the tubing is on the top and more susceptible to potential damage during drywall or finish materials it is also visible which keeps you from hitting it on the underside and causing a huge problem the further you get towards having all the finish materials done. On one of our other custom homes which used staple up, a plumber hit a tube while putting in a shower pan drain and needed to widen the hole around a drain line. It was a lot more difficult to repair that than the Warmboard tube I damaged as he needed to cut up a section of flooring to gain access.

What’s left to be done?

As far as what’s left its pretty much down to case and base and a few other punch list items. I have not been able to work much on the house due to the fact that I need to finish the other two houses that pay the bills and get another one started before winter sets in.

Stay tuned for the next update on NeverSummer’s project and see how Brad and his family are enjoying their Warmboard in the midst of winter!

If you missed the first installment of this series you can read it here.

This moose was not visiting this particular project, but was spotted at a different NeverSummer jobsite.